Want to know more?

Download the brochure for an overview of all the technical details!

Sie wurden automatisch auf unsere englische Website weitergeleitet.

Machining centers for mega and giga castings

Discover the versatile machining possibilities of our machines for mega- and giga-castings, including the powerful G920F5. The "F5" in the name stands for its 5-axis machining capability, perfect for the challenges in automotive engineering, especially for mega- and giga-castings. Its tough design ensures reliable performance under challenging conditions, while its flexible configuration enables a wide range of machining options for a multitude of component designs. The machine is available either with two horizontally or vertically arranged spindles, while a single-spindle version is also available.

The G920F4 is the perfect solution for precise 4-axis machining. It delivers impressive results with two horizontally or vertically aligned spindles and a generous table for parts up to 2,900 mm long. The G920F4 is also available as a single-spindle version. Fast chip-to-chip times and high dynamics together with stability are the key. Our machining centers provide maximum efficiency and precision thanks to the optimized axis drives.

- The linear axes X, Y and Z move the machining spindle

- X-, Y- and Z-axis with optimized dynamics and rigidity

- Next generation 4-axis machining

- Optimal temperature concept

- High manufacturing flexibility – thanks to the modular design and ease of retooling

- Max. part size: Ø 2,000 / L 2,900

- The linear axes X, Y and Z move the machining spindle

- X-, Y- and Z-axis with optimized dynamics and rigidity

- Possibility of 5-axis machining

- Optimal temperature concept

- High manufacturing flexibility – thanks to the modular design and ease of retooling

- Max. part size: Ø 2,000 / L 2,900

- Front or top loading

- Automation to fit your needs

- Loading directly into the work area via double gripper

- Integration of accompanying processes, such as deburring, washing, or marking of the parts

- Standardized components allow quick installation and short commissioning times

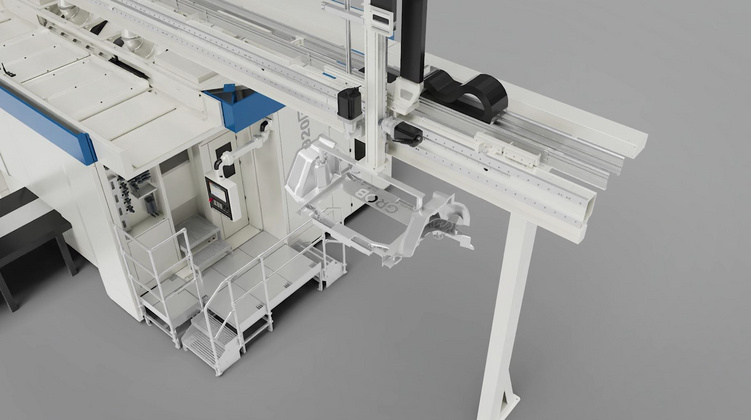

- Fully automated direct loading from above

- High efficiency thanks to simultaneous movement of both the

horizontal and vertical level

- Top loading provides free accessibility of the machine on the ground

- Optionally available as a version with telescope for low hall heights

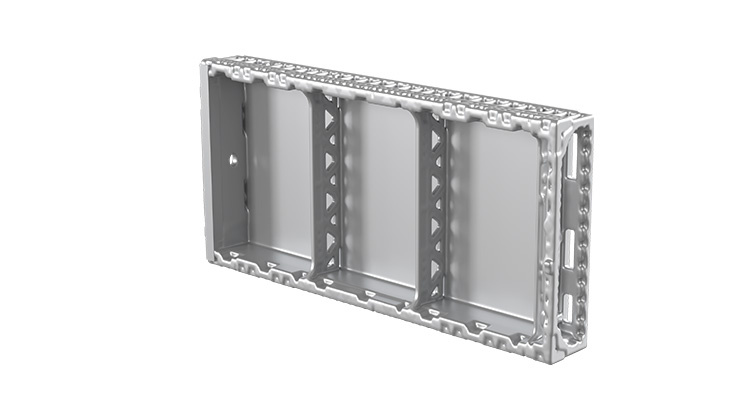

Battery trays, mega- and giga-castings, and much more:

No problems at all for our G900 series. Our machining centers give you access to the future of automotive engineering solutions today!

Battery trays, mega- and giga-castings, and much more:

No problems at all for our G900 series. Our machining centers give you access to the future of automotive engineering solutions today!

Battery trays, mega- and giga-castings, and much more:

No problems at all for our G900 series. Our machining centers give you access to the future of automotive engineering solutions today!

Battery trays, mega- and giga-castings, and much more:

No problems at all for our G900 series. Our machining centers give you access to the future of automotive engineering solutions today!

GROB SYSTEMS, Inc.

Phone: +1 (419) 358-9015

E-mail: info@us.grobgroup.com