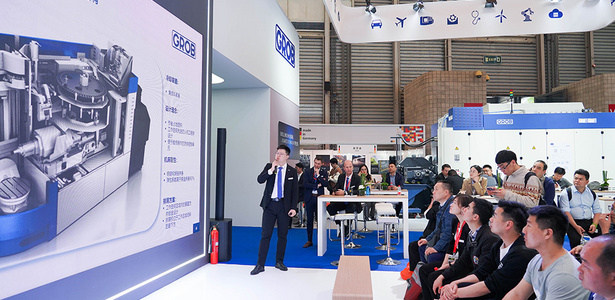

GROB China presented several highlights from GROB automation solutions to machining technology to over 200,000 trade fair visitors at its 425 m² stand. First and foremost, the ultra-modern GRC-R12 robot cell and the G320 machining center, on which the live machining of a cylinder block was demonstrated. Another China innovation was the presentation of the G550T, on which the conventional machining of a transmission gear was shown. The latest GROB developments in the specialist areas of digitalization, service and e-mobility "made by GROB" also attracted a great deal of attention. After the trade fair, we were able to speak with GROB CSO Christian Müller in Shanghai:

How did the trade fair go from your point of view?

Christian Müller: The trade fair was very well attended and we noticed a great deal of interest in our products, particularly at our stand. In China, you can feel the dynamism of the country, the people and the speed at which the country and the technologies are developing.

CCMT, together with its sister fair CIMT, is the most influential mechanical engineering trade fair in China. What significance does it still have against the backdrop of electrification in the automotive industry?

The CCMT is all about machining and so some components such as battery trays, subframes and other electric vehicle components can be seen on CNC machines.

How is GROB's conventional machining and electromobility business developing in China?

GROB has been very successful in the field of conventional machining in China for many years. However, GROB has had to get used to the new "speed" of Chinese customers. They demand CNC machines within two to four months, which means that GROB China has to plan ahead. GROB China has had some very good successes in e-mobility, particularly in connection with assembly. Here, however, the task is somewhat more difficult, as Chinese customers are looking for very simple concepts or solutions that must be able to be replaced by new equipment within a few years of production. GROB is working on a new "access variant" to meet this requirement. Overall, there is an above-average capacity of e-drives in China, which increases the price pressure on every OEM or Tier 1 enormously, which will certainly lead to problems in the long term.

GROB China is currently going through a difficult time. GROB China has had the best capacity utilization of all GROB plants over the last ten years and suddenly it has had the weakest capacity utilization for a few months. What is the reason for this, and are there any signs or hope that the situation will improve after the trade fair?

As already mentioned, capacity utilization in the CNC area is very good. Orders are coming in continuously and at short notice and are being implemented quickly by GROB China. GROB China needs one or two orders in e-mobility this financial year and there are actually a number of projects for GROB China in Greater Asia that could provide a sufficient connection.

To what extent does Dalian play an important role in the GROB plant network and to which markets can GROB products "Made in China" be exported?

China accounted for 12 percent of the GROB Group's order intake in the last financial year. Almost 100 percent of this is handled by GROB China. The predictable phenomenon of "decoupling" has taken place. Local for local is the new trend in China and this is being practiced strongly. GROB China continues to export to the entire ASIA PACIFIC region, including India. A few machines have been exported to Europe in the last twelve months.

There was a "slimmed-down" A(sien)-version of the universal machines. Do these still exist today and for which countries are they built?

The "Access version" of the UM machines still exists. The Asian machines are a GA type that was manufactured entirely locally in China and only sold in China. At the same time, there was the Access machine for Europe only, which was slimmed down to a certain extent for Europe. In future, the new Access machine will be sold to Europe as a localized China machine with exclusive production in China in order to improve the attractiveness of the price. Here, the EU customer receives an entry-level machine at a very good price with the same technology as from the main plant in Mindelheim.