Various tilting rotary table versions are available for the G500, depending on the requirement. The powerful rotary tables are based on the latest torque motor technology and offer optimized dynamics.

Sie wurden automatisch auf unsere englische Website weitergeleitet.

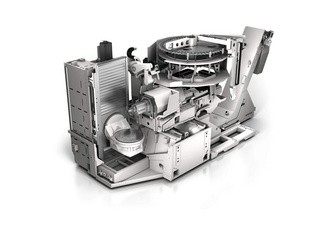

G500

To improve dynamics and rigidity and to achieve a compact configuration according to the modular concept, the motion axes of the G-modules have been divided into tool and part side.

The standardized basic principle of the G-series permits a modularized manufacturing process with shorter throughput times and minimized part costs. This effectively reduces the number of assemblies while permitting a broad range of combinations.

The G-module ensures a fast and flexible response to part modifications and to type changes. This modular principle also makes for easy reusability.

The G-modules are designed for both wet and dry machining. In the system overall, they require only a very small footprint and are optimized for short throughput times. Thanks to constant further development, energy-saving measures are already offered as standard.

The G-series considers increasingly shorter innovation cycles and fast product changes. Its reduced footprint and commissioning effort makes it a flexible partner for all manufacturing tasks and any process modification.

Fast tool change through an intelligent magazine to motorized spindle arrangement

For meeting the toughest cutting requirements

Almost limitless machining potentials thanks to the largest possible swivel range

Uninterrupted part machining with chip disposal by a scraper-type conveyor

| Industry | Automotive |

| Material | Aluminium alloy |

| Motorized spindle | 12,000 rpm |

| Power/torque | 40 kW/161.4 Nm |

| Industry | Automotive |

| Material | Aluminium alloy |

| Motorized spindle | 18,000 rpm |

| Power/torque | 29 kW/34.6 Nm |

| Industry | Automotive |

| Material | Aluminium alloy |

| Motorized spindle | 18,000 rpm |

| Power/torque | 29 kW/34.6 Nm |

| Industry | Automotive |

| Material | Aluminium alloy |

| Motorized spindle | 18,000 rpm |

| Power/torque | 29 kW/34.6 Nm |

Tilting rotary tables

Spindle versions

Besides the broad range of spindles, the motorized spindles designed and produced by GROB itself are the preferred choice for optimized process design. These are optimally matched to the G500 and have optimized quality features.

Tool magazine

GROB tool magazine technology is set apart by fast chip-to-chip times, a smaller space requirement and optimized accessibility. Choose the right solution for you.

Control systems

Choose between the latest and most powerful CNC control systems from market leaders for the G500:

- SIEMENS (standard)

- FANUC (option)

Automation solutions

Draw on the experience we have garnered over several decades and benefit from the automation technology we tailor to meet your needs – from solutions with part storage systems to highly flexible manufacturing lines.

GROB SYSTEMS, Inc.

Phone: +1 (419) 358-9015

E-mail: info@us.grobgroup.com

International support

Sites

Directions