- HSK-A63, 47 Nm, 12,000 rpm

- HSK-A63, 47 Nm, 18,000 rpm

- HSK-A63, 83 Nm, 12,000 rpm

- HSK-A63, 86 Nm, 17,000 rpm

- HSK-A100, 185.5 Nm, 12,000 rpm

- HSK-A100, 340 Nm, 10,000 rpm

Sie wurden automatisch auf unsere englische Website weitergeleitet.

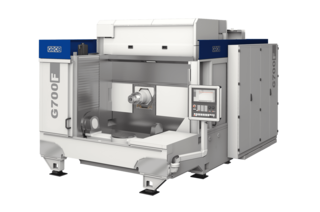

G700F

The axis combination is based on the tried and proven G-series GROB machine concept with horizontal spindle position and guarantees free chip fall and optimized heat dissipation.

The modular and standardized machine components guarantee the best possible GROB product quality.

Available with manual or automatic front loading or automatic top loading.

Unrestricted interference diameter of 1,500 mm in the A- and B-axis.

For meeting the toughest cutting requirements

Almost limitless machining potentials thanks to the largest possible swivel range

Uninterrupted part machining with chip disposal by a scraper-type conveyor

Optimized access and simple orientation for preventive maintenance and inspection

| Industry | Automotive |

| Material | Aluminium alloy |

| Motorized spindle | 18,000 rpm |

| Power/torque | 29 kW/34.6 Nm |

| Industry | Automotive |

| Material | Aluminium alloy |

| Motorized spindle | 18,000 rpm |

| Power/torque | 29 kW/34.6 Nm |

| Industry | Automotive |

| Material | Aluminium alloy |

| Motorized spindle | 18,000 rpm |

| Power/torque | 29 kW/34.6 Nm |

| Industry | Automotive |

| Material | Aluminium alloy |

| Motorized spindle | 12,000 rpm |

| Power/torque | 40 kW/161.4 Nm |

| Industry | Automotive |

| Material | Aluminium alloy |

| Motorized spindle | 18,000 rpm |

| Power/torque | 20 kW/26 Nm |

Spindle versions

Besides the broad range of spindles, the motorized spindles designed and produced by GROB itself are the preferred choice for optimized process design. These are optimally matched to the G700F and have optimized quality features.

Tool magazine

- Single disk-type tool magazine

- Double disk-type tool magazine

Control systems

Choose between modern and powerful CNC control systems from market leaders for the G700F.

Automation solutions

GROB SYSTEMS, Inc.

Phone: +1 (419) 358-9015

E-mail: info@us.grobgroup.com

International support

Sites

Directions